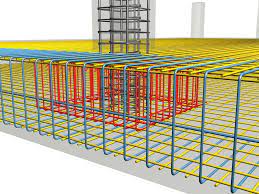

Rebar detailing is an important but frequently overlooked aspect of the construction process. It entails developing comprehensive drawings of reinforcing steel or rebar installation, bending, and assembly. These designs serve as guidance for rebar installers on the job. While rebar detailing may appear to be a tedious chore, using professional rebar detailing services can dramatically improve your building projects.

The Value of Correct Rebar Detailing

Concrete constructions are strengthened and supported by rebar. It strengthens the concrete and makes it resistant to tensile stresses. Rebar, on the other hand, must be precisely put and built according to an engineer’s design. Inadequate rebar detailing can jeopardize a project’s structural integrity and potentially pose safety issues. Expert rebar detailers know how to correctly analyze engineering drawings and produce error-free drawings. They take constructability into account during the detailing process to ensure that rebar can be installed easily in the field. A good project requires precise rebar details.

Remote Estimation Using Streamlined Processes

Rebar detailing was traditionally done on-site, which slowed down the construction process. However, using remote estimating allows professional detailers to complete rebar detailing off-site. It shortens project timelines in several ways:

Engineering designs can be provided digitally to an off-site detailing team, avoiding delays caused by physical plan transmission.

Detailing work can begin immediately without the need for on-site mobilization. It reduces the time it takes from design to implementation.

Drawings are returned electronically, which speeds up the review process. Without the need for physical document exchanges, comments may be answered quickly.

Installation teams are provided with comprehensive shop drawings in advance, allowing for advanced material ordering and fabrication work. It cuts down on delays once the rebar arrives on-site.

Saving Money Through Efficiency

While Rebar estimator detailing services are not free, they can save money on building projects in the long run. Detailers with experience spot mistakes in engineering drawings, saving costly change orders and rework down the line. They also optimize rebar quantities to maximize material utilization. Remote estimating saves time spent on logistical coordination, which shortens overall project timelines. Shorter schedules result in cheaper indirect expenditures such as equipment leasing and site monitoring.

Detailers’ emphasis on constructability leads to simpler shop drawings that expedite field installation. Less time is spent on issue resolution and bespoke fabrication. Their knowledge helps to eliminate installation errors that can cause delays if rebar needs to be reassembled. Overall, experienced rebar detailing services improve efficiency and minimize total project costs when compared to managing detailing in-house or on-site.

Maintaining Quality and Compliance Standards

All construction projects must adhere to building codes as well as industry quality requirements. However, comprehending and executing these rules might be difficult. Experienced rebar detailing businesses are well-versed in the most recent codes as well as best practices. They know how to create rebar that will withstand inspections and meet engineering criteria. Construction teams receive an added layer of compliance assurance by outsourcing detailing to professionals.

Detailers also use quality control techniques to ensure that drawings are free of errors and omissions before they are distributed. They make use of specialist software as well as years of cumulative experience. Outsourcing rebar detailing to a specialized firm relieves internal project teams of the compliance burden. Construction managers may rest assured that all rebar design and documentation is up to code.

Increased Installation Safety

Working with heavy rebar is one of the most dangerous aspects of construction. A rebar that has been improperly constructed or assembled has the potential to collapse and cause injury. Expert rebar detailing, on the other hand, addresses safety during both the detailing and installation phases.

Detailers create rebar that is easy to install and position with as few lifts as possible. They feature assembly instructions and component markings to make installation easier. As a result, field staff spend less time performing dangerous lifting or positioning of rebar mats.

In addition, detailed shop drawings remove uncertainties. Installers are given specific instructions on how to connect each rebar piece. They avoid potentially hazardous scenarios of field improvisation. Overall, outsourcing rebar detailing to safety-conscious experts improves the safety of on-site installation teams.

Changes in Engineering Design that are Coordinated

Throughout the design development process, expert rebar detailing businesses collaborate closely with project engineers. They have prior expertise in handling engineering design modifications and ensuring that all rebar documentation is in sync. Minor design changes can be easily incorporated into shop drawings without disturbance schedules.

Detailers analyze potential concerns that may arise as a result of suggested alterations such as increased loads or different materials. Before finalization, they collaborate with engineers to fix concerns such as increased congestion. This collaborative strategy protects construction teams from the financial consequences of unanticipated adjustments later in the field. Overall, rebar detailing outsourcing enables a coordinated interface with engineers during design changes.

Material Management and Fabrication

Some rebar detailing businesses also provide value-added fabrication services. They can prepare rebar for installation by cutting, bending, and assembling components after creating accurate shop drawings. It supplies construction crews with completely produced rebar bundles that are ready for installation.

Detailing companies often handle material sourcing and shipping for just-in-time delivery. They keep track of quantities as they modify designs to avoid shortages or over-ordering. On-site storage and staging locations are better controlled. Construction crews are provided with orderly load lists and given visibility into incoming goods. Overall, outsourcing rebar detailing and related manufacturing simplifies project material management.

Experienced Professionals Provide Peace of Mind

The most important benefit of outsourcing rebar detailing for construction managers is peace of mind. As their primary business activity, expert businesses specialize in this technical labor. They make use of modern BIM modeling, specialist rebar software, and institutional collective knowledge. Construction teams receive extra confidence knowing that their rebar design and documentation are in the hands of highly qualified professionals.

For complex projects, there is no risk of a shortage of in-house resources or expertise. Managers avoid problems caused by inexperienced internal teams racing to complete rebar jobs. They get a centralized point of contact for all rebar coordination and documentation. Outsourcing detailing to professionals enables building project managers to concentrate on their main strengths while still ensuring high-quality rebar solutions.

Conclusion

In conclusion, using professional rebar detailing services delivers various benefits in addition to accuracy. Remote Estimation Construction projects benefit from streamlined procedures, cost efficiencies, compliance assurance, increased safety, and risk reduction overall. Outsourcing this technical work to specialized organizations improves all stages of a project, from design to installation. Construction managers benefit significantly from utilizing competent rebar detailing pros.